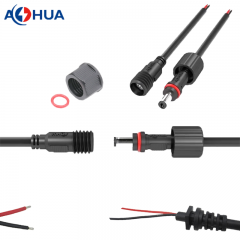

AOHUA M12 M15 M16 M20 Assembly Male Female Cable Connector is soldered on the wire.

Welding techniques have some important requirements to ensure weld quality and safety. The following are some of the common requirements:

1. Temperature control: Welding temperature is one of the most important parameters in the welding process. The control of welding temperature is essential to ensure the quality of the weld. Different materials and welding methods have different temperature requirements. It is important to select the appropriate temperature range for the particular material and welding process, and to ensure that stable temperature control is maintained throughout the welding process.

2. Temperature monitoring: During the welding process, appropriate temperature monitoring equipment needs to be used to monitor the temperature of the weld area in real time. This can be done with equipment such as thermocouples, infrared cameras or temperature sensors. Monitoring the temperature can help detect anomalies in time and take appropriate measures to adjust welding parameters to ensure quality.

3. Control of welding speed: Welding speed is also one of the parameters to be controlled during the welding process. Too fast or too slow welding speed may lead to a reduction in the quality of the weld. To control the welding speed, the operator should adjust the welding speed reasonably according to the welding material and welding process requirements to ensure the quality of the weld.

4. Protective gas selection and control: Certain welding processes need to be carried out in an inert gas environment to prevent oxidation and the presence of other contaminants. Select the appropriate shielding gas and ensure that the flow and quality of the shielding gas is properly controlled during the welding process to ensure that the environment in the welding area meets the requirements.

5. Cleaning and pre-treatment: The surface of the workpiece should be cleaned, decontaminated and pre-treated before welding is carried out. This includes the removal of impurities such as oil, rust, oxides, etc. to ensure that the welding area has ideal surface conditions to improve the quality of the weld.

6. Operator skills: The skills and experience of the operator during the welding process is also a key factor in ensuring the quality of the weld. Operators should have good knowledge and skills in welding technology, be able to operate the welding equipment correctly, and adjust the welding parameters as needed.

In summary, welding technology requirements involve temperature control, temperature monitoring, welding speed control, shielding gas control, cleaning and pre-treatment, as well as operator skills and experience. Quality and safety in the welding process can be ensured through proper control and operation.

Tel : 86-0755-89999957 /

Tel : 86-0755-89999957 /  Email : colin@aohuadz.com

Email : colin@aohuadz.com

86-0755-89999957

86-0755-89999957 colin@aohuadz.com

colin@aohuadz.com