Hello, everyone, pls pay attention! There's some good news to announce!

Our new connector product has been successfully developed! Our metal assembly series products(L20) are now officially available for purchase!

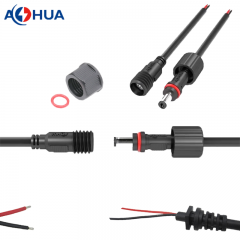

This is an AOHUA metal circular waterproof connector, L20 Type Connector an industrial-grade electrical connection component primarily used for cable termination in outdoor/harsh environments. Below is a detailed analysis:

1. Product Type and Core Features

- Type: Circular aviation plug-style waterproof connector (assembly type), with the diagram illustrating the combined structure of "plug + socket + cable".

- Waterproof Rating: Typically achieves IP67/IP68 (dustproof and immersion-resistant), suitable for outdoor, industrial equipment, LED lighting and similar applications.

- Core Functionality: Enables rapid cable interconnection + sealed protection, preventing water/dust ingress that could cause short circuits or malfunctions.

- Metal plug/socket: Silver-coloured metal casing (typically stainless steel or alloy) featuring a threaded locking mechanism (ensuring a secure connection), with gold-plated pins inside (for excellent conductivity).

-

Cable end assembly: Black plastic waterproof sheath + multi-core coloured cable (with visible yellow, red, blue and other cores), some fitted with retaining clips (to prevent cable pulling).

- Accessories: Dust cover (protects unmated sockets), panel mounting bracket (for securing to equipment casing).

3. Application Scenarios

These connectors are primarily used in:

- Cable connections for outdoor LED street lighting and landscape illumination;

- Signal/power transmission for industrial equipment and sensors;

- Electrical systems in humid/vibratory environments such as marine vessels, motor vehicles, and livestock farming.

Below is a checklist of key selection criteria for standard circular waterproof connectors, covering core parameters such as pin count, voltage/current ratings, and protection ratings. Combined with scenario-based compatibility logic, this facilitates rapid matching to requirements:

Scene Type

Core requirements

Recommended protection rating

Housing material

Number of cores

Installation method

Recommended options (examples)

Outdoor LED lighting

Waterproof, dustproof, low-cost

IP67

Nylon

2-4PIN

Panel / Wire-to-wire

Aohua M12 Series Universal Model

Industrial sensors

Vibration-resistant, signal stability

IP67/IP68

stainless steel

4-8PIN

Wire-to-wire + anti-loosening structure

TE M12 Sensor Dedicated Model

Ship / Marine Environment

Corrosion-resistant, suitable for prolonged immersion

IP68

316 stainless steel

4-12PIN

Panel + flange mounting

Amphenol Marine Grade

Industrial Equipment Power Transmission

High current, temperature-resistant

IP67

Zinc alloy (heavy gauge)

2-6PIN

Wire-to-wire + Locking mechanism

AOHUA

Military / Aviation Equipment

Temperature-resistant, interference-resistant, highly reliable

IP68+MIL Certification

Titanium alloy / Stainless steel

8-24PIN

Panel + Anti-misinsertion structure

Tyco Military-Grade Series

Parameter type

Key Selection Criteria

Example of Scenario Adaptation

PIN Number

1. Select based on transmission requirements: Power transmission (2–4 cores), Signal + Power hybrid (4–8 cores), Multi-signal (8–24 cores);

2. Reserve 1–2 cores for redundancy (to avoid inconvenience during future expansion).

LED lighting (2-4 cores), charging points (3-6 cores), sensors (4-8 cores)

Rated current

1. Single-core current ≥ 1.2 times the actual operating current (to prevent overloading and overheating);

2. For high-current applications (e.g., charging points), select 30–50A; for standard applications, select 5–10A.

Outdoor charging points (30–50A), industrial equipment (10–15A), LED lighting (5–8A)

Rated voltage

1. For AC scenarios, ≥1.5 times the operating voltage; for DC scenarios, ≥2 times the operating voltage;

2. For standard scenarios, select 250V–500V; for high-voltage scenarios (e.g., industrial equipment), select 1000V or above.

Domestic charging points (250V), industrial power transmission (500V), high-voltage equipment (1000V+)

Contact resistance

Prioritise ≤50mΩ (lower values indicate more stable conductivity), and for high-frequency signal transmission scenarios, select ≤10mΩ.

Sensor signal transmission (≤10 mΩ), standard power transmission (≤50 mΩ)

Insulation resistance

At ambient temperature ≥100 MΩ, after exposure to humid conditions ≥10 MΩ (to prevent leakage current)

Outdoor / damp environments (≥10 MΩ), dry indoor environments (≥100 MΩ)

II. Protection and Environmental Parameter Selection (Adapting to Application Scenarios, Ensuring Durability)

III. Mechanical Structure Selection (Compatibility, Installation and Usage Methods)

IV. Compliance and Additional Requirements Selection (Ensuring Security and Compatibility)

V. Prioritising Model Selection (Avoiding Pitfalls)

-

First determine the application scenario (outdoor / industrial / marine, etc.) → establish the required protection rating and environmental resistance parameters;

-

Next, match the electrical requirements (number of cores, current/voltage) → to prevent transmission overload or signal instability;

-

Then confirm the installation method(panel-mounted/wire-to-wire) to suit the equipment structure

-

Finally, add compliance and special features (certification, flame retardancy, anti-misinsertion) → to ensure safety and compatibility.

Quick Selection Guide for Common Scenarios (Direct Application)

5.The pricing of metal circular waterproof connectors is primarily influenced by the following categories of factors:

1. The material and craftsmanship of the product itself

-

Material: The stainless steel casing (corrosion-resistant but costly) is more expensive than standard alloys; gold/silver-plated contact pins (superior conductivity and oxidation resistance) are pricier than tin-plated copper; fluororubber waterproof seals (high/low temperature tolerance) are costlier than conventional rubber.

-

Processing: Complex techniques such as precision threading, surface electroplating (corrosion protection), and sealed structural design contribute to increased costs.

2. Specifications and Performance Requirements

-

Number of cores: 8-core is more expensive than 4-core (due to more complex materials and construction).

-

Protection rating: IP68 (suitable for prolonged immersion) is more expensive than IP67 (suitable for short-term immersion).

-

Special properties: Customised features such as high-temperature resistance (e.g. 150°C), high-pressure resistance, and vibration/shock resistance will increase the price.

3. Brand and Quality Certification

-

International brands (such as TE, Amphenol) or well-known domestic brands (such as Aohua) command higher prices than smaller manufacturers due to significant investments in research and development and quality control.

-

Products requiring certifications such as ISO, UL, or RoHS (e.g., for medical or aerospace applications) are more expensive owing to the substantial testing costs involved.

4. Procurement and Market Factors

-

Procurement volume:Bulk purchases (e.g., 1,000 units) command a significantly lower unit price than small batches (e.g., 10 units).

-

Customisation requirements: Customised variants with non-standard dimensions or functionalities command several times the price of standard models due to the substantial costs associated with tooling and development.

-

Supply and demand relationship: Prices may fluctuate when raw materials (copper, stainless steel) experience price increases or supply chain shortages.

5. Application Scenarios

-

Industrial/outdoor applications (requiring high protection) are more expensive than standard indoor scenarios;

-

Connectors for extreme environments such as military or aviation use may cost over ten times the price of standard models.

Tel : 86-0755-89999957 /

Tel : 86-0755-89999957 /  Email : colin@aohuadz.com

Email : colin@aohuadz.com

86-0755-89999957

86-0755-89999957 colin@aohuadz.com

colin@aohuadz.com